The leather activities begin with husbandry. The conditions of this step are capital for the quality of the final leather.

Moreover, an animal not vaccinated or badly healed, has a higher risk of injury, having parasites and being bitten. We will find on theses skins scars that will worsen the quality of the leather.

THE SLAUGHTERHOUSE

The way the slaughter is done is essential. If an animal is stressed out when it dies, that will negatively affect the quality of the skins.

More the demand for meat increase, more skins will be available for the leather industry. The trader in skins rapidly contacts the slaughterhouses because the skins are wet products (3/4 the weight of skin is made by water) and so extremely putrescible. If they wait for too long, they degrade in a few hours. They need to be rapidly dehydrated to stop the development of bacterias and microbes that deteriorate the skin.

Many methods exist:

- Salting (most used because it is simpler and cheaper)

- Drying

- Conservation by the cold

- Freezing

etc.

The trader will then weight and sort out the salted skins (raw skins) by most homogenous batches in quality and weight. This step is very important because it allows the tanner to offer the most homogenous leather batches.

Then, the tanner buys the batches depending on his type of fabrication and the demands of the customer.

His experience allows him to recognize the skins that will become quality leather. It is a very important choice, that, again, will influence the quality of the final leather.

THE PREPARATION OF THE SKINS AND THE TANNING PROCESS

In general, the tanneries are specialized in one type of skin ( lamb, calf, bovines, etc.). It is this specialization that gives the name of the tannery.

Furthermore, the leather industry can use very toxic products, toxic for the environment and humans. We work with french tanneries that are under very strict laws on this subject. We assure us, by doing this, that the leathers used in our shoes or others are made with the respect of the environment.

The skins come in boxes directly from the slaughterhouses, where they have already undergone a first cleaning and degreasing treatment, and a first cooling.

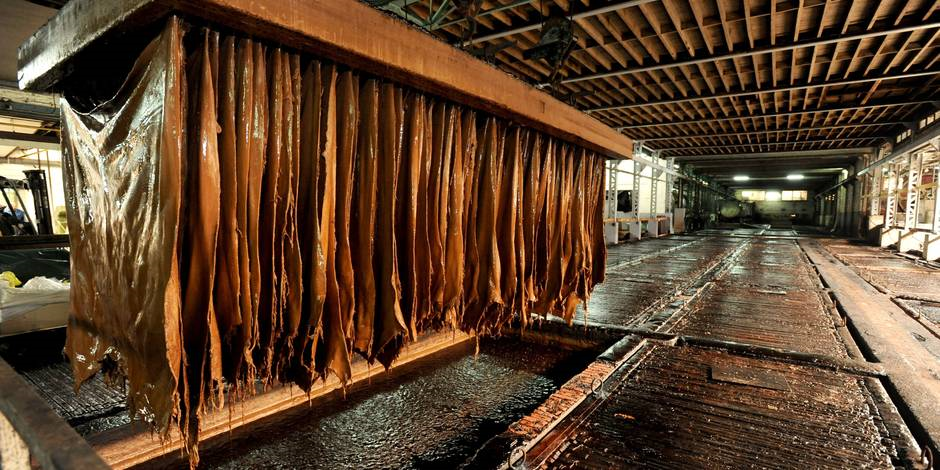

Then, the skins are hanged to go in the refrigerator where they are cooled to 7 °C, and later directed to or the salting, or the cold storage.

We salt the skins by laying them on a big board and salting them with an automatic machine. They are then kept for a week.

When the skins are drained, they are brought to the desalting machine, sorted out by the standard categories, depending on the client’s specific orders. Thus, we form complete batches.

Then, the pallets are weight again for a second control and directly brought to the refrigerator. Thus, the batches that will be sent to our client are finished.

Furthermore, we cut a part of the goods in Tuscany. That brings the best cut to satisfy our clients that want croupons, shoulders and bellies.

TRUST US AND TEST OUR KNOWLEDGE THAT ASSETS NUMEROUS YEARS OF PROFESSIONAL EXPERIENCE